Convert the Bachmann 0n30 Gondola to 55n3

Bachmann's On30 Gondola/Flatcar is about a foot too wide in 55n3 for the early era of narrow gauge. It is easy to make a typical narrow gauge gondola. The gondola just has to be lowered to make a late era gondola.

Make a wooden block to hold the car body. This will protect the steps.

Remove the buffer block with a Jeweler's Saw. If you don't have a Jeweler's saw get one. They are great.

Slice off the nut-bolt-washers with a NEW sharp single edge razor blade. Save them in a Baggie.

Be more careful than me.

Slice off the nut-bolt-washers with a NEW sharp single edge razor blade. Save them in a Baggie.

Be more careful than me.

Carefully slice off the ratchet from the deck. Slide it onto the brake wheel shaft so it won't get lost.

Draw a line down the deck slightly wider than the truck lugs on the bottom. Draw a second line a scale foot away. Cut the ends with a fine blade up to the deck line.

Make a few passes with a utility knife and snap off the car body.

Do the same to the second line.

Do the same to the second line.

Careful snapping the remaining piece. DON'T bend it up the plastic will fracture. D-oh!!!

Correct the error by scribing a new line and sanding the piece to the line.

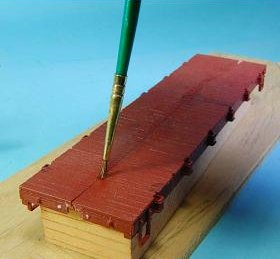

Slosh the joint with MEK. Don't worry about the deck finish. Squeeze the deck sections together. The joint should be wet enough to have a bead ooze out. Align the boards.

MEK can be obtained at hardware stores.

MEK can be obtained at hardware stores.

Place the deck on a flat surface. Place the wood block on the body. Let it dry.

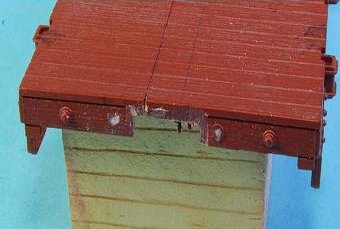

Place "Bondo" down the joint.

Remove the "Bondo" from the board joint with a pencil.

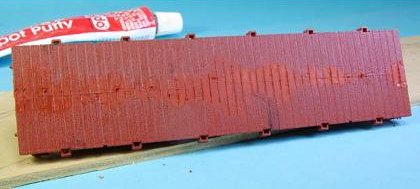

After the "Bondo" is dry. Sand the deck until almost all the stock "grain" is gone. Use 100 grit sand paper.

Add "grain" with 50 grit paper. Use the sandpaper to "wash" out any troublesome joint areas.

Rescribe the joint lines with the backside of an Xacto #11 blade.

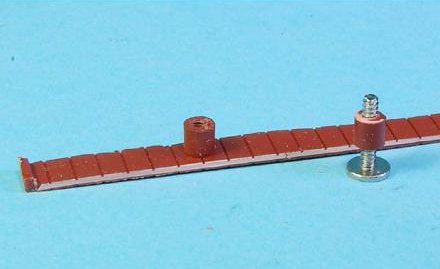

Slice off the mounting lugs and increase the threads by screwing them on the truck screws.

Shorten the truck screws to 1/4" long.

Shorten the truck screws to 1/4" long.

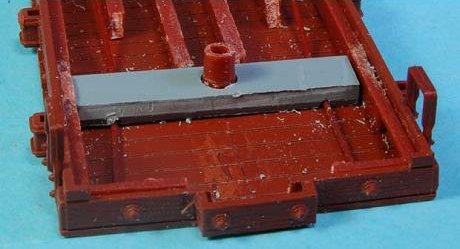

Cut the center beam from the frame. Use it to locate the truck lugs. Glue the lugs to the body.

Check with the centersill that lugs are in the right location.

Mark the centersill on the endbeam and relieve the endbeam. Don't remove the ridge on the body at the end beam.

Glue the buffer block back on the end beam.

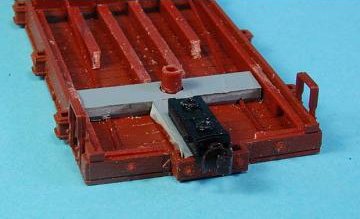

Slice off the bolster lug and glue it on the truck mounting lug. It is tapered so don't glue it like the photo. The sliced end is down.

Temporarily tack the centersill on the body. Fit the queenpost beam on the outer frame to the centersill.

Make a bolster from 1/8 x 1/4 material. Cut the centersill back. Relieve the timbers on the outside frame to clear the truck wheels.

Drill a clearance hole in the bolster and relieve the bolster to clear the truss rod and it's lugs.

The next two pictures are from the boxcar article. D-oh!!!!

Assemble the frame together and glue the truss rods to the queenposts. Make sure the turnbuckles are vertical.

Make a coupler mounting block. Relieve the block to clear the body.

I attach my couplers before gluing the block in place.

The flatcar portion finished.

Scribe and snap the endpiece at the upright.

Place the pieces in the car and mark the inner piece. Sand the piece to fit.

The backside will need filling and sanding no matter what. The ejection pin dimples have to be filled.

Finish the deck and interior. Here are pictures from the old On30 site showing the method I used. The gondola was done using brown inks.

Click here to go to the section on weathering flat car decks.

Click here to go to the section on weathering flat car decks.