Smaller Drivers for the Athearn/Roundhouse 4-6-0

This is an old article from the Pacific Coastline site.

The Athearn/Roundhouse 2-6-0 has 66" drivers which are atypical for that species. Bowser makes a 56" variety and they make the locomotive a real freight hauler. The older Roundhouse locomotives have 1/8" diameter axles and don't require the axle slots to be modified.

The Athearn/Roundhouse 2-6-0 has 66" drivers which are atypical for that species. Bowser makes a 56" variety and they make the locomotive a real freight hauler. The older Roundhouse locomotives have 1/8" diameter axles and don't require the axle slots to be modified.

You will need the following parts from Bowser:

3 sets Bowser 56" SPK DRIVER PLAIN #1-17900

4 each Bowser SHORT CRANK PIN #1-1720

2 each Bowser LONG CRANK PIN #1-1721

A NWSL wheel puller and a #2 hex wrench are also needed.

3 sets Bowser 56" SPK DRIVER PLAIN #1-17900

4 each Bowser SHORT CRANK PIN #1-1720

2 each Bowser LONG CRANK PIN #1-1721

A NWSL wheel puller and a #2 hex wrench are also needed.

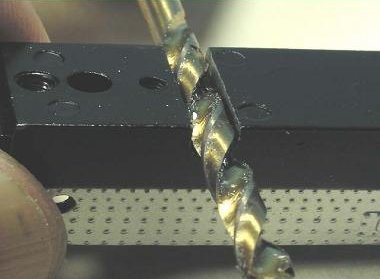

The Athearn/Roundhouse drivers have a .118 diameter axle and the Bowser drives have a .123 diameter axle. I broach out the axle slot by rotating a 1/8 diameter drill in the slot.

The new axle slots have the original 1/8" axle slot and have a small ridge to accomodate the smaller driver axle. After the slot is enlarged with the drill the Bowser driver will snap down into the slot and turn freely. Gently file the tabs on the vertical walls so the driver slip into the slot. Run the 1/8" drill back and forth until there is a "stripe" in the bottom of the driver slot. Clip off the pilot it will have to be replaced.

Mark the crank pin location on the axle with a scriber. Use the un-insulated driver.This will be used in quartering the driver when it is returned to the axle. NWSL has a "Quarter" if you are squeamish about quartering by eye.

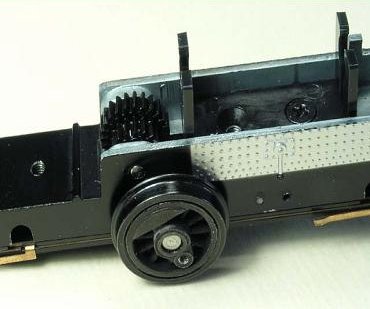

Push the Athearn/Roundhouse gear onto the axle. The collared part of the gear will slide onto the shaft. Use the "Puller" to finish pushing the gear on the axle. Locate the gear using the original axle.

Remount the Bowser driver on the axle. Adjust the gear so that the axle gear doesn't interfere with the idler gear in the axle's total range of lateral motion. Mount the motor and apply power. It should run with no binding.

Drill out the side rods with a #46(.081 diameter) drill. Mount a second set of drivers and see if there is any binding. If the second set is successful move onto the final set.