The First Garratt

By Malcolm Savage

Continental Modeller - Mar/Apr 1985

Reproduced courtesy of Continental Modeller

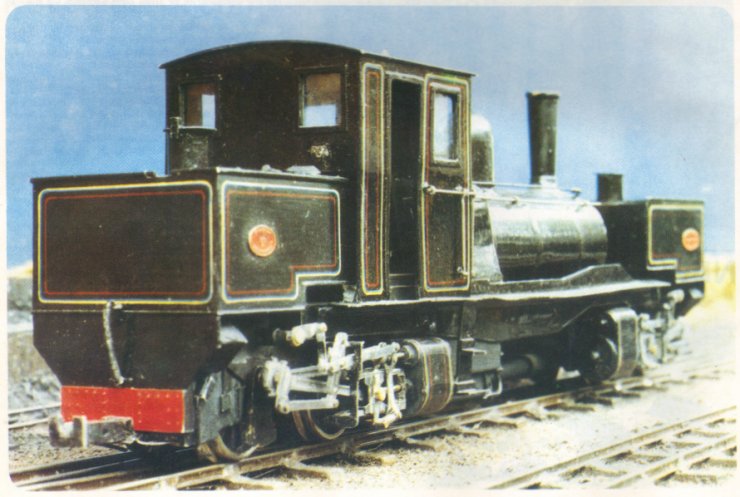

In my article 'The Last Garratt' in Continental Modeller Nov/Dec 1983 I mentioned that I had already made a model of the first Garratt. This article describes that model, also built to a scale of 5½mm to the foot and running on 12mm gauge track.

The Prototype

The Garratt locomotive was the last major type of articulated locomotive developed and also the most successful.

At the time of its introduction the other main articulated types were the Meyer, the Mallet and the Fairlie, all

of which had disadvantages of one sort or another. The Fairlie had the expense of and subsequent maintenance of

two boilers. A large firebox could be accommodated between the bogies but width was limited by the presence of

the driver and fireman on either side. The Mallet and the Meyer both suffered from a shallow firebox positioned

over coupled wheels. The Mallet also had a very long boiler with a considerable overhang which kept its maximum

speed down to 30 mph at most. Kitson eventually solved the Meyer's problem by separating the bogies and dropping

the firebox between, but were still left with a boiler whose diameter was restricted by side water tanks. Garratt's

idea separated the bogies even further allowing the whole boiler unit to fit between. Because there was no overhang

the locomotive was more stable than the other articulateds that were around at that time. Water and coal were mounted

directly onto the bogies with the intention of making them oscillate less. His original sketches had large driving

wheels suggesting that he realised his design would be capable of high speeds. And finally the design allowed for the

ideal form of boiler, large in diameter and short in length.

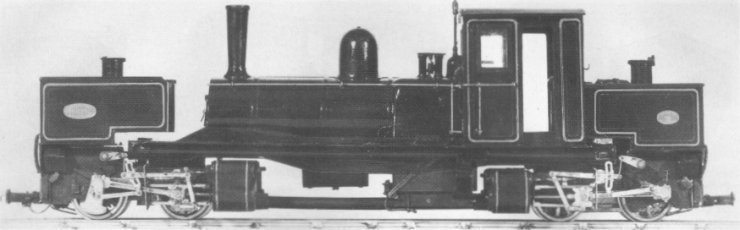

In the lead up to the first Garratt, Beyer Peacock produced, in April 1907, two designs of 0-4-4-0 Mallet for the Tasmanian Government Railway's (TGR) 2' gauge system. They followed this in July with a design for a 2' gauge 0-4-4-0 double Fairlie for the New South Wales Government Railway (NSWGR). In October of the same year an 0-4-0 + 0-4-0 Garratt design was produced as a replacement for the Fairlie. A year later a similar but large design was produced for NSWGR but this time for their 2' 6" gauge system. In April 1908 the first Garratt design for the TGR was produced, based on the first design for NSWGR. It was a heavier locomotive and used simple expansion but the TGR wanted a compound instead. While discussion took place over this locomotive other schemes were being drawn up including one to convert Beyer Peacock's own 1' 6" gauge works shunter to a Garratt. The TGR finally ordered the first Garratt in January 1909 to be followed shortly by a second. By the end of 1909 no fewer than forty-five schemes had been produced for Garratt from 1' 6" gauge to 5' 6" gauge.

K1 spent its working life on the TGR Dundas Tramway pulling 40-45 ton loads up 1 in 25 gradients and round 99' radius curves in a very damp climate. After the line closed in 1930 it remained stored in its shed until 1947 at which time Beyer Peacock bought it back. It remained with them until 1966 when the works closed. Rather than see it go for scrap the Festiniog Railway found the money to purchase this historic locomotive. After many years in storage it is now on display in the National Railway Museum in York.

The Model

The model of K1 had a chequered history before it finally performed well enough to enter service. Construction of most of

the model presented no problems but trying to get it to work was another matter entirely. All previous models had used a

K's TT motor bogie as the power unit so my first scheme for K1 also utilised the same bogie. This was my big mistake. The

K's bogie scales at 5ft but K1 has a wheelbase of only 4ft. While it was possible to reduce the wheelbase to 4' 6" it was

not possible to reduce it any further unless the commutator switched places with the worm mounted at the end. I decided

that it was worth trying and so destruction of the motor began. The wires were unsoldered from the commutator which was then

pulled off. The worm that had already been removed had five holes drilled through it. Short lengths of insulated wire were

fed through the holes after the worm had been soldered back on the shaft. The commutator was forced back into place and all

the wires were soldered up. New holes were drilled in the poles to take the brush gear and the motor was reassembled and

tested. And it actually worked up to a point. I had also decided to have eight wheel drive, so the front bogie was fitted

with gears and worms connected to the rear bogie by a drive shaft fitted with universal joints. By this stage the basic body

had been completed and I was able to assemble the model and try it out. All it did was smoke realistically although the smoke

was appearing from all the wrong places. I assumed that the extra friction of the front bogie was the cause of the trouble and

so this was removed and the loco tried again. It was only slightly better than before. It did move, just, still smoked a lot

and eventually ground to a halt. Examination of the motor showed that the commutator, originally forced on to the shaft, pulled

off and forced on again, had split and turned getting out of alignment with the poles of the armature. At this stage I nearly

consigned the whole lot to the dustbin and it was some time before I made further attempts to get it to work.

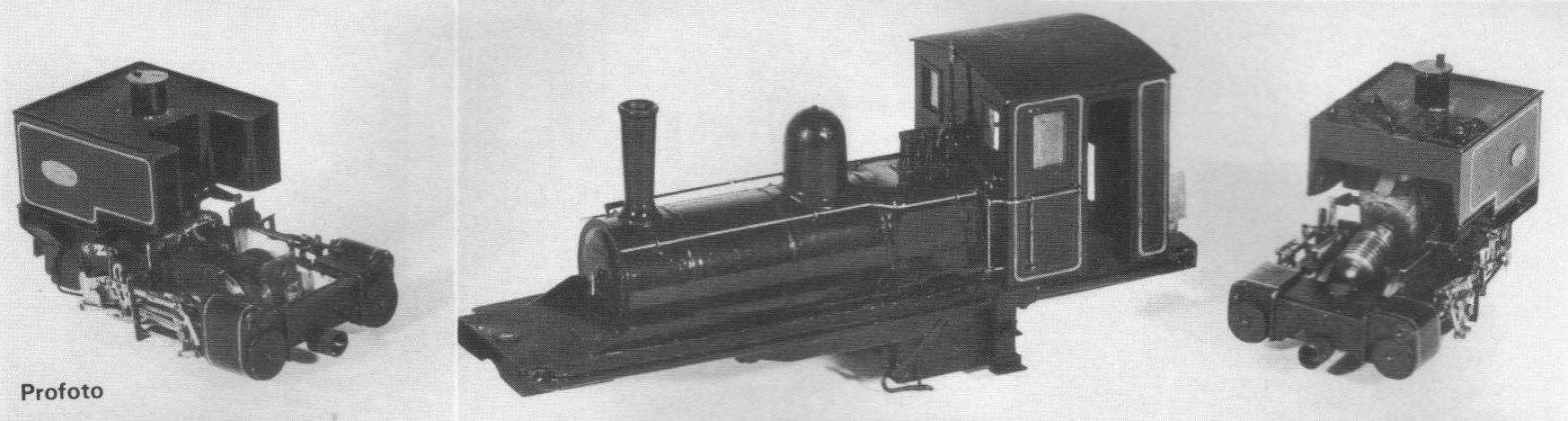

When I did return to the model I decided that I would have to make a proper mechanism. All the problems had arisen because I had doubted my ability to make frames, cranks and coupling rods well enough for the mechanism to be driven off one axle only. New brass frames were made for the rear bogie only. The front bogie retains its original frames and the axles are still fitted with gears. All the wheels of front and rear bogies run on inside frames. The outside frames are dummies made of Plastikard and carry cylinders, sandboxes and details of axleboxes and springs. The model runs on Jackson 14mm spoked tender wheels and is powered by a K's Mk II motor through Romford 40-1 gears. The axles were long enough, after the wheels were pushed in to the correct gauge, for the cranks which were force fitted onto the ends to clear the outside frames. The coupling rod and axle holes were drilled fractionally undersize and were opened out with a broach until crankpins and axles were a close running fit. When the cranks had been fitted and the coupling rods had been mounted on the crankpins. I was amazed to find that it all ran freely and no opening of any of the holes was required. This has never happened since! The coupling and connecting rods were made from strips of mild steel which were originally Eheim trolley bus wires. The fluting is made by filing and sawing after the ends had been bent down. Once the required depth has been achieved the ends are bent back up again and the whole is filed smooth. The remainder of the valve rods are made from two thicknesses of tinplate. This allows the ends to be separated to form the forks. Each set of valve gear is a separate unit that is held in place at the cylinder end by the valve and piston rods and at the motion bracket end by a clip behind the frame. The four sets of valve gear for this locomotive were the first that I had constructed properly and fortunately they look and work well.

The whole of the superstructure is made from Plastikard apart from the usual metal fittings, such as chimney, dome and handrails. The boiler was the last one that I had constructed from Plastikard sheet rolled around plastic discs and this together with the fact that the whole structure is made of fairly thin Plastikard has meant that the model is rather fragile and has shown a slight tendency to warp. This particular model also says something for Plastikard construction, as during its first outing to an exhibition it was knocked off the layout onto the floor. The few pieces that fell off and the joints that were split open were welded together with very little damage to the paintwork, and it was soon running again.

The model is finished in black lined yellow, blue and red, and fitted with home-made photo-etched number and worksplates. It has proved to be one of the quietest and smoothest running locomotives on the model railway, in spite of all the attempts that were made originally to make it work.

Finally can anyone give me any information about rolling stock on the Tasmanian Government Railway Dundas Tramway? It would be nice to have some appropriate rolling stock to run behind the model K1.