Festiniog Gravity Slate Train

by Malcolm Savage

Photographs by the author.

Railway Modeller - May 1986

Reproduced courtesy of Railway Modeller

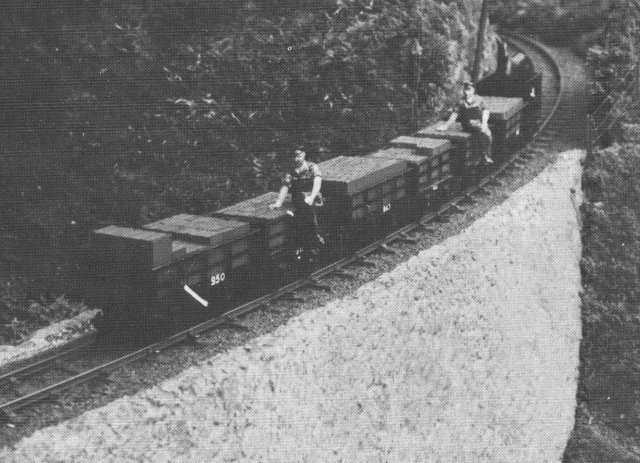

Festiniog Railway gravity slate train crossing the embankment.

For some time I had been toying with the idea of providing the Gwynant Valley Railway with that most Festiniog of trains, the gravity slate train but it was only earlier this year that I finally started putting ideas into practice by building a motorised slate wagon.

The gravity slate train goes back to the beginning of the Festiniog Railway. In those early days slate was worked down by gravity in two stages. Inclines over the Moelwyn mountains prevented through gravity working but with the building of the Moelwyn tunnel in 1842 it was possible to run trains from Dinas through to Portmadoc. Each down train consisted of five or six slate wagons with a 'Dandy' or horse box at the rear. The line was worked in sections and the horses, which were used to pull the empty wagons uphill, were changed at each section. As traffic increased the trains increased in length, with a Dandy to every five wagons.

When steam locomotives were introduced in 1863 gravity trains increased in number because gravity passenger trains were also run. The practice was for the goods stock to run down first with a brake van in front. This would be followed by the slate train which in turn would be followed by the locomotive running light. At the rear would come the passenger train again headed by a brake van. By the early 1870's gravity power had been continued until 1940. It was common for gravity slate trains to consist of 80-100 wagons and occasionally more although this was discouraged. For trains with less than 80 wagons two brakesmen were required. Above 80 three were required. The first two wagons in each train were braked, thereafter approximately one in five wagons were braked and the wagons were to be arranged in the train so that all the brake handles were on the valley side. Brakes could be either ratchet or simple lever, the latter being preferred by the brakesmen as they could be tied off to the top rail of the wagon.

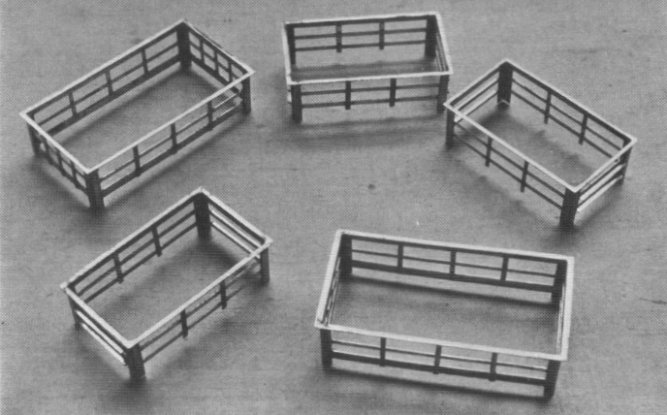

The earlier wagons were timber framed and bodies as were the dandies. Some had inside frames. Later wagons were all iron. The majority of wagons were of 2-ton capacity although many 3-ton capacity wagons were also built. These were not very popular because they were too wide to be loaded easily and too wide to pass on inclines. Three types of wheels were used. Early wheels had oval holes with spokes cast in relief. Later, when casting techniques had improved, the wheels had curved spokes. Disc wheels could also be found mostly under braked wagons.

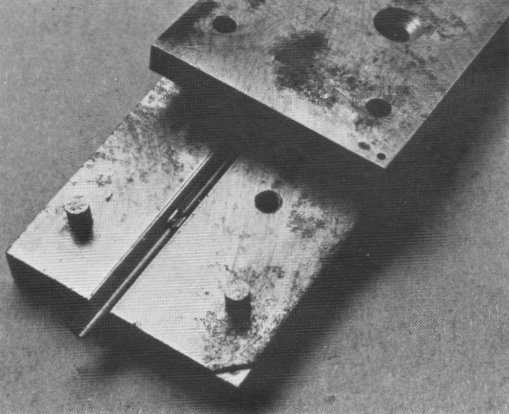

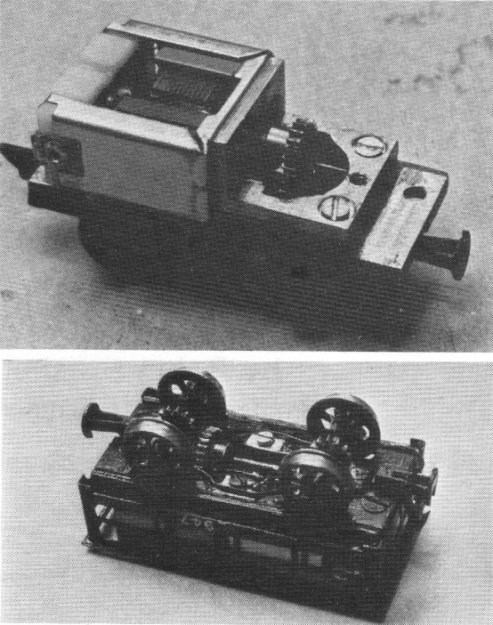

Press for making 1mm and 2mm angles.

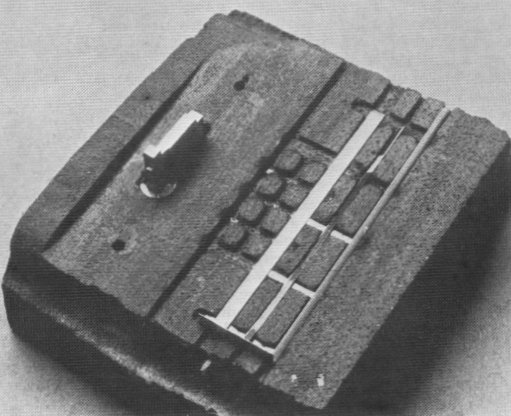

Jig for assembling 3-ton wagon bodies and couplings.

Assembled 2-ton and 3-ton slate wagon bodies.

The first model slate wagons that I made about 18 years ago were rather crudely constructed from Plasticard. The only good thing I can say about these wagons is that they only took half an hour each to build. In order that they should look as spidery as possible they were made from 10 thou Plasticard, consequently they are very fragile and I am surprised that they have lasted as long as they have. My modelling techniques have improved over the years but the thought of trying to make the bodies in metal was so off-putting that it was not until last year that I started to tackle the problem. An offer, by a friend, of the use of his guillotine to cut up all the strip that was necessary, was the first hurdle overcome. The second was to build a press to fold 2mm and 4mm wide strip to form the two sizes of angle necessary. This was milled from two blocks of mild steel. Pairs of notches were milled into the sides of the V-groove to locate accurately the two widths of strip. The material used for the bodies is 10 thou tinplate cut from car oil cans. Two jigs were made for assembling the bodies; one for the 2-ton and one for the 3-ton wagons. These were milled from blocks of hard wood, using old small drills ground square as milling cutters. One of the blocks also has a small jig for soldering coupling bodies onto the heads. The body is located in place by a block of aluminium. Assembly of the wagon body takes about 30 minutes using solder paint.

Parts for couplings and the method of construction.

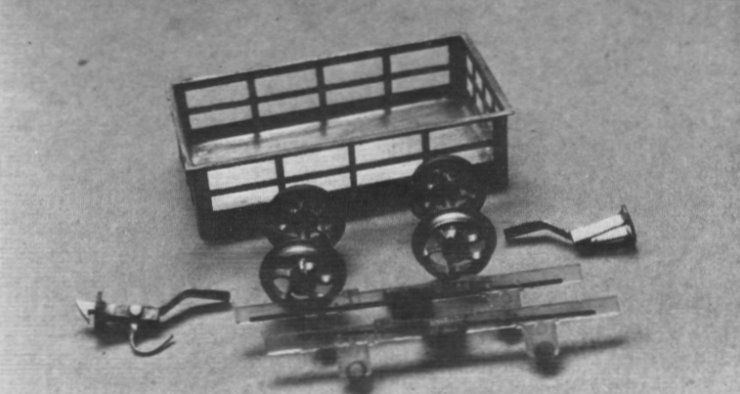

Set of parts for a 3-ton slate wagon.

I have been experimenting for some time with resin-casting for various detail parts such as some of the pieces of my G16 Garratt and bogie side-frames, but the wagon side frames are much finer and more fragile. First attempts were intended to have holes drilled, after casting, to take brass bearings, but drilling caused the resin to shatter. Later attempts incorporated the bearing during the casting. The casting also contains a length of wire for reinforcing and also a brass bracket for soldering to the wagon floor. This can be done if the iron is applied for the barest minimum time.

The wheels are Jackson 9mm TT wagon wheels. Each has six holes drilled radially using a dividing head on the lathe. These holes are then filed either oval or to form curved spokes. The former type of wheel takes three or four minutes the latter fifteen. Each axle has its end reduced to about half its diameter to fit into the small bushes in the side frames.

Couplings

The couplings are made from brass with a tin bracket for attachment to the body. The various parts are milled to

shape and are parted using a circular saw. The coupling hooks are finished with files and are fitted with iron

tails for magnetic uncoupling. The angled bracket that is used to attach the coupling allows for adjustment in the

coupling height.

After completing several of these wagons thoughts again turned to a motorised slate wagon. Apart from deciding on the basic layout, horizontal motor driving through reduction gears to a layshaft and finally through worms and gears to both axles, no details had been worked out. Nevertheless I plunged into construction which is why, by the time it was completed, it was on its second chassis, reduction gears, motor and wheels! The motor would not run smoothly enough, the gears were too large and the chassis was not wide enough to allow for fixing of the side frames and body.

Motorised slate wagon.

The chassis was milled from a block of brass. Four pillars were left to support the wheels and a slot was milled down the centre. Careful setting up allowed the layshaft holes to be drilled from both ends and the axle hole to be drilled through the pillars. The motor was mounted on a separate bracket screwed to the top of the chassis. The reduction gears are Swiss instrument gears and the worms and worm-wheels are Minitrix. The total reduction is 1:15. The pickups were made from phosphor-bronze. One is screwed directly to the chassis, the other to a plastic bush. One brush holder on the motor is shorted out to the motor casing, the other has a wire soldered to it the other end of which has a tag which locates under the insulated pick-up fixing screw. The projecting ends of the axles were removed from the wheels and resin frames were cast without bearings or fixing brackets. These were fixed in place with cyanoacrylate adhesive. It was at this stage on the second chassis that it was found that the first motor, an Eggerbahn, was too jerky and it was replaced by a small Hong Kong-made motor that I had bought from Studiolith many years ago. This was found to be a much smoother runner when fitted to the chassis. Fortunately I was able to mount it on the same bracket using the same fixing holes. However I did have to bush the gear as this motor had a smaller diameter shaft. All that now remained was the fitting of the body and a block of lead to improve adhesion.

Mechanism

It was of course necessary to conceal the mechanism with a slate load. This was made from numerous pieces of 10 thou

Plasticard. More loads were made for five more wagons. The individual pieces of varying sizes make the loads look more

realistic.

The Dandy was assembled, without the aid of jigs, from tinplate. Unfortunately, because of limitations set by the wide gauge, slightly overwide wheels and the method of construction of the chassis, the body is a scale 8" too wide.

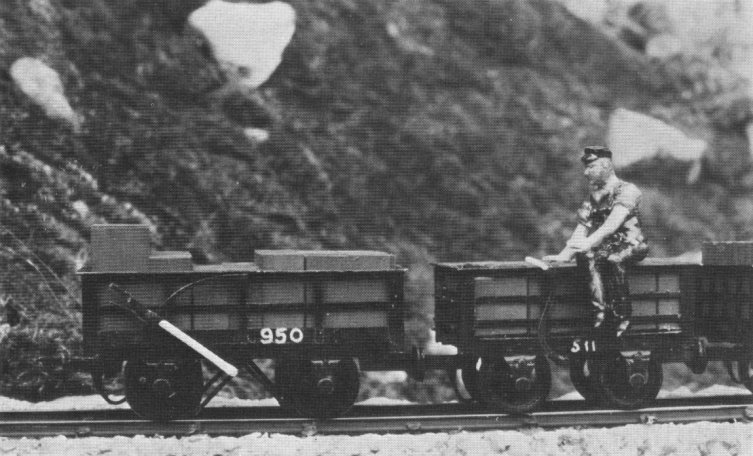

The front of the gravity slate train, correctly having the first two wagons braked.

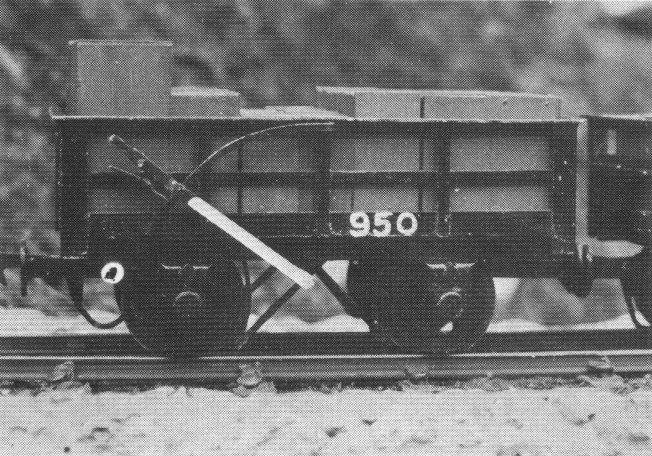

Braked 3-ton slate wagon.

All the wagons were spray painted with Humbrol coal black and hand numbered in white. The two men are much modified Slaters 7mm scale seated figures. The horse is a problem. The ones shown in the photographs are only temporary. They are approximately the right size overall but are too thin. The Slaters 7mm horse may prove too difficult to scale down, so for the time being the 'Dandy' will probably spend most of its time in goods trains as a coal wagon and the gravity slate train will represent a steam era train without horse accommodation. If we do solve the problem of the horse another problem will be created - how to mechanise it to work the uphill empties!

The end of the gravity train with a horse in the Dandy.