Llugwy Valley

Narrow gauge in 5½mm scale

by David Etheridge

David describes Malcolm Savage's new layout, built from experience

with its predecessor the Gwynant Valley (RM October 1984).

Railway Modeller - May 1995

Reproduced courtesy of Railway Modeller

Gwynant Valley Developments

Malcolm Savage's layout certainly put 5.5mm scale (1/55) back on the modelling map, leading to the formation of the 5.5mm Association. As any exhibitor will

know, putting your creation in front of the public is guaranteed to bring out any shortcomings or potential problems. As lessons were learned and problems

solved, so the layout was upgraded and improved. Regulars at exhibitions would look to see the differences (mainly in trackwork) at each outing.

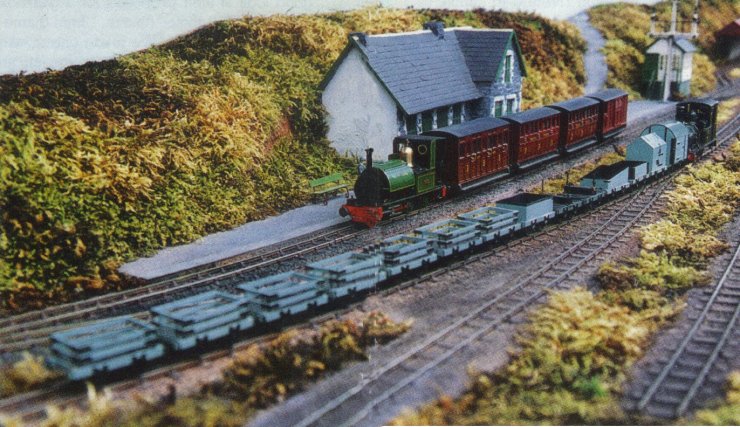

'Earl of Merioneth' emerges from the bridge into the station.

Malcolm described the drawbacks in the design of the Gwynant Valley in 55 News, the Association's Newsletter. They lay in its origins as a terminus; converted to a through station, these gave problems in operation (see RM October 1984 for the track plan). The single loop was not only used for passing passenger trains, but also formed part of the headshunt and siding area; in practice, loop usage could and did block other station movements. Not for nothing was Gwynant Valley dubbed the Clapham Junction of the Narrow Gauge!

While a lone operator might not find this a problem, with two operators at exhibitions the limitations of the track plan were becoming apparent. As the oldest part of the layout dated back to the mid 1970s, Malcolm decided that a fresh start was needed. Festiniog Gala 90 was the last time that the Gwynant Valley was exhibited and, as a result of this appearance, it was sold to a Festiniog member for installation in the roof of Minfordd Hostel, This done, a start could be made on a new layout.

Llugwy Valley

Nothing teaches like experience; so new methods have been used in baseboard construction, track design and materials. The Llugwy Valley Railway is based, once

again, on the NWNG's General Undertaking from Beddgelert to Bettws-y-Coed. The station, Pont Cyfyng, is on the site of the proposed connection between the NWNG

and the Moel Siabod Tramway by the A5 near Capel Curig. The quarry line itself is described in Volume 3 of J I C Boyd's Narrow Gauge Railways in North

Caernarvonshire on page 187.

Layout concept

The model presupposes that the quarry line was built before the main line, so that the station layout is fundamentally different from most narrow gauge track

designs. Here it comprises a double loop end to end, or you can regard it as a long loop with a crossover in the middle. One half of the loop gives passing

facilities for the main line, whilst the second half gives connections to the quarry branch, sidings and shed. As the station has a single platform, passenger

trains are passed through the loop Talyllyn style.

'Talyllyn' stands at the platform as 'Dolgoch' arrives with a freight train from the branch.

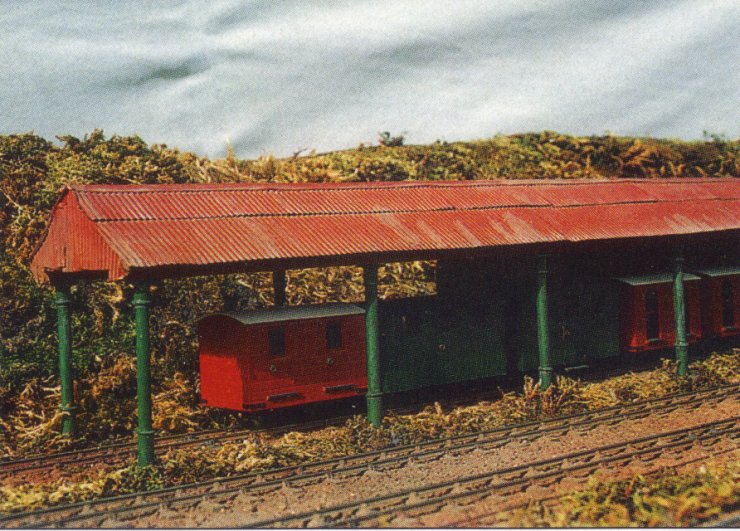

The carriage shed with Talyllyn coaches.

The loco shed is presumed to be part of the original quarry line, which itself connects offstage to the storage yard loops, giving in effect a third loop through the station. The goods yard has two sidings plus headshunt, nearly twice the length of those on the Gwynant Valley. The carriage shed is designed to hold a normal length rake of coaches; normally the quarrymen's rake is held there, but in fact any terminating train's stock can use it.

One feature not immediately apparent in the design is that Malcolm has just about eliminated all straight track from the plan to give sweeping curves through the station. Even the carriage shed is built on a curve the radius of which works out at around fifty (actual) feet!

Storage Yard

On the Gwynant Valley the sidings consisted of six loops of equal length. As these were outgrown, extra sidings were added. Unfortunately the loops were not as

long as the station site, so they could not hold trains made up in the station. Fine if you positively like intensive shunting away from the gaze of the public,

but not really on for exhibitions.

On the Llugwy Valley, the storage sidings comprise nine loops of varying lengths. Each is split electrically into two so that eighteen trains can be held, and the longest trains can now be easily handled.

In the middle road you will find a central trough cut out of the baseboard: this is to mount a new storage cassette system that Malcolm is working on. The cassettes feature movable sides that hold the stock in place when removed from the layout, and the system is still in development. In common with many narrow gauge layouts, the layout has more stock available than it can handle at one time!

Baseboards

These reflect current thinking, being of 6mm ply for both tops and sideframes, giving lightness and strength, and constructed without any internal cross

bracing. This gives ample room for electrical systems, and also for the legs to fold up inside the layout. 1" square pieces of wood have been installed in

two places on the framing: the angle between the sides and the surface, and the bottom edges of the sides. Following unwanted flexible results with the

first board, Malcolm used a double skin of 6mm ply on the sides below the level of the surface board.

'Taliesin' drifts into the station.

'Dennis' and train leaving the tunnel and entering the passing loop.

Further ply pieces were then fixed over the 1" square wood to form box sections. On the outside edges of the boards, the box section is inset by 1" to give space for cup hook mountings for curtains around the layout.

There are eight boards in all: three for the station area, three storage siding boards, and two linking sections at either end. The centre board of each group of three has two sets of legs, while the outer boards have one set each. The linking boards at each end have no legs, which needs a certain amount of dexterity when fitting them in place. Instead of the plug-in legs of the earlier layout, the legs on Llugwy Valley now fold up inside the boards, to keep them clear of magnets and switches around the layout, and are locked in and out of position; more on this anon.

Lighting

Lights are mounted in sockets on the rear of the boards and cantilevered out over the layout for convenience (and to stop young children hanging onto them, as

happened on the Gwynant Valley). Lighting standards consist of steel conduit with the cable running down the inside.

At the lower end of each conduit is a square socket constructed from wood and aluminium angle, to prevent any movement. Here the lighting cable drops through the bottom of the board and picks up mains voltage from a socket mounted on the side of the control panel.

Shelf Edge Solutions

The really new ground in baseboard construction comes in the form of ex-GPO shelf edge connectors for both electric and mechanical usage between

boards. This idea was suggested by long-time Gwynant operator and 5.5mm Association supremo Mike Chinery. These consist of a large horizontally

mounted U shaped channel, into which are hooked smaller vertically mounted U shaped channel sections. Inside the smaller ones are banks of relays

and connectors which engage with matching connections on the horizontal channel. If you're as confused as I am from the description, then the

accompanying photo should be worth the proverbial thousand words!

The Beyer-Garratt K1 pulls into the goods loop with a long train of Festiniog wagons.

The shed is made from card covered with Faller stone paper. Slates are also of card.

The connectors give both mechanical and electrical connections between boards that don't move, dispensing with the nut and bolt approach. Have you ever found that you've lost that all-important last wingnut while crouching underneath the layout and supporting half a baseboard on one shoulder?

In order to make up a standard modular connection, suitable pieces were cut from the various sections using a jig. These were then welded to steel and the whole construction rivetted to similar sized pieces of 6mm ply, then glued to the sides of the baseboards. The connectors themselves project through holes in the end boards. Welding facilities were courtesy of Llugwy Valley group member Alec Carr, who made the units up at night school.

The result is a board connection so strong that you can omit the legs at the far end of the outer board and it will be held in place by its connection to the centre board. It also makes for very fast setting up and breaking down times for the layout at exhibitions. Malcolm calculates that the Llugwy Valley can be up and operating from scratch in fifteen minutes, including lighting and curtains, although it has been done in five!

Leg Locks

How do you get baseboard legs to lock up and down in position, without struts of any kind? This was the next subject to be tackled. Time for more metalwork

and welding. Wooden legs are braced together in pairs; at the top of each is a short length of steel angle. In the angle is milled a vertical slot, and above

that slot, a notch. The slots fit over steel studs welded into plates screwed to the inside of the baseboard sides. On these latter plates is a second stud

directly above the first, and a third (square) stud set at right angles in the assembled position. The photo should make things clear.

The weight of the boards is carried on the studs that sit at the bottom of the slots, and the notches locate around the upper studs which stop the legs swinging to and fro. When you lift the boards up, the legs drop and the notches come away from the upper studs, allowing the legs to swing free. When you swing the legs up inside the baseboards and pull them on their slots, the edge of the angle slides under the square stud. As this happens, a small notch filed in the edge of the angle hooks onto the corner of the square stud, which stops it sliding out again by itself.

In practice the system works well, though experience showed up the need for extra bracing on the centre board to counteract end-to-end movement on the layout as a whole.

Track and Electrics

Malcolm now uses C&L 4mm track components on a Sundeala trackbed. In 5.5mm scale, the two-bolt chairs and rail are a close approximation to FR measurements.

C&L point sleeper strip, which is slightly wider than the plain track variety, is used throughout to give the correct look needed for narrow gauge, together

with fine scale 00 and TT wheel standards.

Electrics are comprehensive: track laying was described by Malcolm as very time consuming, as each length of rail (including check rails) has its own dropwire underneath the baseboards. Rail chairs are first cut in half, the dropwire is set into the middle, and then routed through a drilled hole in the sleeper, trackbed and baseboard. The two halves of the chair are then stuck back together to give an invisible connection. This system results in the underside of the baseboard having a mirror image of the track layout above in wiring, but this belt and braces approach does give electrical continuity throughout the layout, allied with good running.

Track uses C & L 4mm scale components. Ballast is crushed decomposing firebrick from an incinerator.

Another trackwork hint from Malcolm: cleaning the inner sides of rails as well as the tops ensures that locos pick up the current reliably, and dispenses with the need for Relco units on the Llugwy Valley (wonderful products though they are). For convenience, all electrics are placed as close together as possible, with transformers inside the control panels. Despite the recommendations of other modellers, Malcolm has found no problems with this system. The two controllers themselves are feedback types built by Mike Chinery from a plan in the model railway press. These really are excellent (as I found from personal experience at the Merseyside Exhibition in 1994), being very smooth in operation and giving superb results from the (often criticised) K's Mark 2 motors that power most of the Llugwy Valley locos. Although the controllers can start occasionally with a jerk before they sense the feedback from the motor, Malcolm says you get used to it!

Each controller has its own panel and section switches, and uses the shelf edge system to connect the panels to the baseboards. Toolbox catches keep the connections tight between them. The left hand controller covers the station area and half way round the main line at each end, while the right hand one covers the main line and storage loops alone. Track plans are mounted by the controllers to indicate track feeds, isolating and point pushbuttons. Each section has a two-way plus centre-off switch for controller allocation, and there are plenty of isolating switches on sidings: six in the loco shed siding alone. With the sophisticated sectioning there are 90 wires from each panel into the layout, which gives exceptional flexibility of use on a par with Zero 1 (yes, people still ask). Some untypical layout movements are possible. For instance, you can move one loco in the middle of the shed road from one isolating section to another, while fenced in by a second loco, which can itself be controlled independently. Another example: two trains can follow each other around the layout under full independent control, all achieved by judicious section switching.

Isolating sections are indicated with white marks on the rail facing the operating (non-viewing) side, while uncoupling magnet positioning is indicated with yellow marks on the rail sides. Uncoupling magnets are homemade with a U-shaped core and the coil wound round one end.

Point control is courtesy of a 24v AC capacitor discharge unit controlling vintage H&M point motors (rescued from the Gwynant Valley layout when it was sold), which are totally reliable in use. Any problems with point usage will invariably be in the mechanical connections.

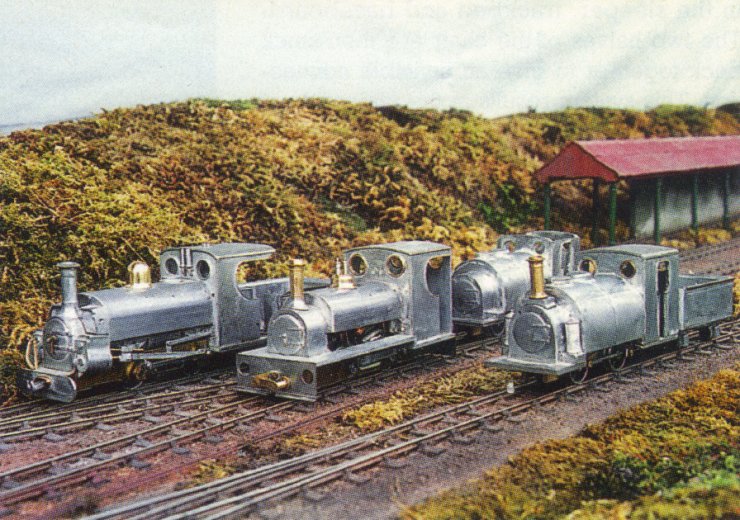

Triple double Fairlies! 'James Spooner', 'Merddin Emrys' and 'Earl of Merioneth' from GEM kits on etched chassis.

Scenery

From the three-sided approach of the Gwynant Valley, Malcolm has gone for a single section on the Llugwy Valley, giving a more unified scenic setting

for the eye to take in. No backscene is used, but the scenery is raised behind the station area to provide the visual break. Following its successful use

on the Gwynant Valley, real moss is again used for foliage, set into a base mix of soil (thicker than before) and resin W, hopefully to get the moss to

grow and last longer. Though the scenery can be watered to give subtle variations in colour and a very natural look, there have been drawbacks: as moss

can crack stone in the wild when growing, overwatering caused the Sundeala base to expand and warp, thereby breaking electrical connections. Malcolm says

that things looked a bit dicey until the Sundeala dried out and resumed its former shape! He thinks moss is not as successful here as it was on the Gwynant

Valley, although it still gives better results than more familiar techniques, and the scenery often generates questions at exhibitions from observers.

The buildings on the Llugwy Valley do use familiar techniques, with a few suprises.

The loco shed has been made by James Taylor from Faller embossed stone paper on a card base, while the station building uses carved car body filler resin over card formers for wall textures. Roof slates are paper overlays, and the signal box is of plasticard construction. The carriage shed uses a variety of materials: brass tube and wire columns, a ply base and roof ridge and a roof of card overlaid with corrugated brass sheets made using Meccano gears. The carriage shed is not only on a 50' radius curve, but crosses a board joint; as a result, half the columns have telescopic ends and springs at the bottom of their respective sockets to allow for any relative movement between boards. I'm still trying to work out which half they are!

New Locos, Stock and 5.5mm Kits

Most of the Llugwy Valley stock has been featured in various articles in RM over the years, and the formation of the 5.5mm Association has meant that most of

Malcolm's time has been spent producing kits and parts for fellow members. However, new models are on the way. As a result of meeting ex 5.5mm modellers at

exhibitions, Malcolm purchased several GEM loco kits in varying conditions. As a result, three double Fairlies are (at the time of writing) approaching completion

and provided the impetus behind the new etched brass Fairlie chassis kit, which uses Tenshodo power.

Carriage shed with assorted F.R. quarrymen's vehicles inside.

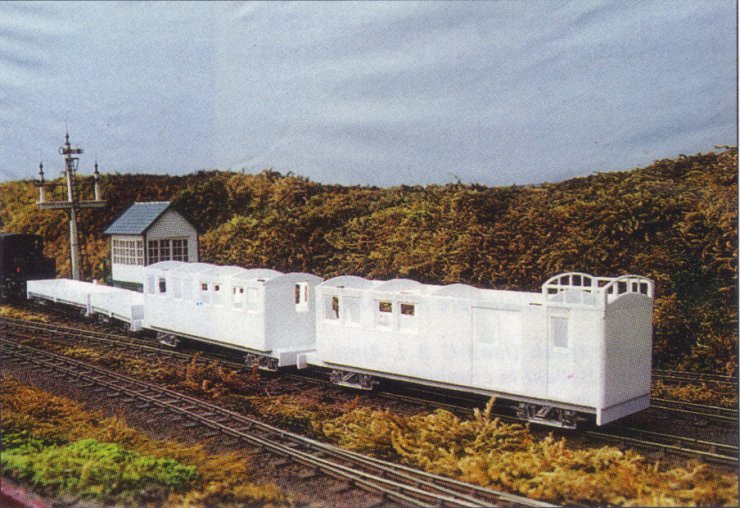

Locos under construction. 'Linda', 'Cackler' and 'Palmerston' with 'Little Giant' in the background.

One will be a new model of Earl of Merioneth, another is Merddin Emrys (pre 1955), modified with shortened tanks and added lower boiler flare, and the last is a model of James Spooner, which has a brass tube parallel boiler and turned brass boiler fittings added to the original GEM parts. To go with James Spooner will be models of the original FR coach no. 14 and a curly-roofed van. Together with some more bugboxes, these will be finished in the FR red and cream livery of the 1890s.

Another GEM Prince is planned, this time with a new chassis, to become Little Giant. Plans are afoot for an etched brass chassis for Prince in two wheelbase lengths for both versions of the England locos; from there it is a short step to a chassis for the prototype Fairlie Little Wonder. More FR Quarrymen's coaches are planned, again using the new 5.5mm etched chassis kit. The first etched slate wagon was developed following commercial success with a 7mm version, and version 2 is in hand for 5.5mm scale, Completing the range of etched brass products are two types of chassis for quarry Hunslet locos.

As a result of Malcolm's article on Dundas Tramway K1 in Continental Modeller March/April 1985, helpful readers around the world sent him details of rolling stock. Two Dundas Tramway coaches are approaching completion, with plans in hand for two more coaches and six wagons, although the brake rigging on each bogie win be a modelling event in itself!

In the last article on Gwynant Valley Developments (RM May 1990), Malcolm described his new freelance diesel that used a cut-down Airfix Drewry shunter body. Another version of this has been completed with a higher coupling height to match up with and make a partner for Malcolm's W&L loco and stock. To cap the stock story off, rumours persist of a freelance tram loco comprising a Dolgoch boiler and a K's tram loco body. We shall see!

The odds and ends. Roundhouse HO track cleaner regauged, two modified Airfix diesels and 'Thomas' to keep the children happy.

Carriages and wagons of the North East Dundas tramway under construction.